Scale up your cannabis production through automation

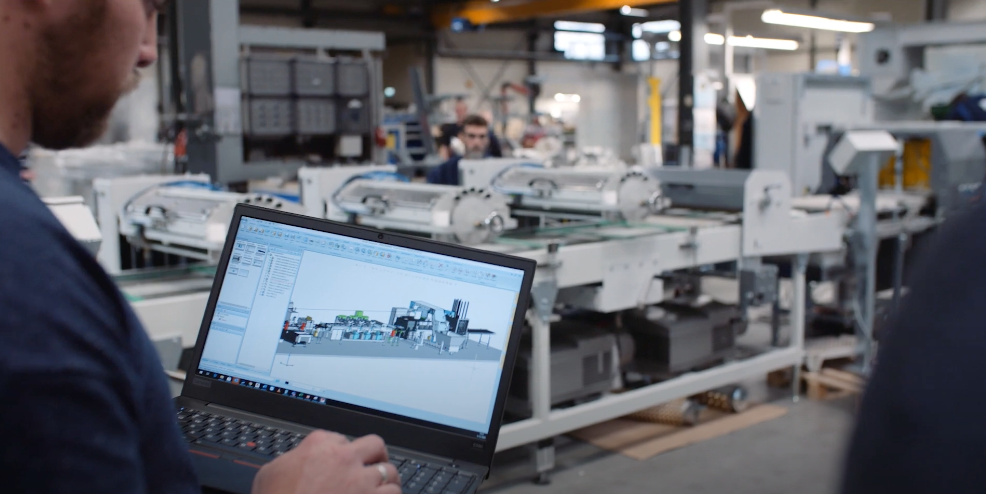

As a proud member of the LCC, Viscon contributes a vast and diversified range of solutions for every stage of cannabis growing and processing. Our expertise is built upon decades’ worth of experience throughout the horticultural sector, which now allows us to be frontrunners in the commercial cultivation of cannabis. We provide our partners with the techniques and equipment to grow the highest quality of plants, as efficiently as possible. The focus on automation in every part of the process results in a cost-effective, scalable cannabis production.

Viscons’ areas of expertise ranges from storing and handling cannabis seeds, clones and tissue culture plants to the packaging of the end-product itself. If you want a more in-depth description of specific subjects, the Viscon webpage will be linked per topic.